The importance of acceptance tests before delivering industrial equipment

Factory equipment compliance is high priority since it is key to efficient quality production. To guarantee equipment compliance, acceptance tests must be performed before the delivery and before the final installation of the equipment. These tests are carried out at the factory by the manufacturer in collaboration with the customer’s project team. Working together, they can exchange on the functionalities and performance of the equipment while sharing technical expertise. Consequently, the manufacturer can guarantee that the equipment meets the quality requirements of the customer as defined in the specifications. This prevents any future malfunction that would require troubleshooting with additional resources, travel and costs.

Remote assistance: a key resource for carrying out acceptance tests in the factory

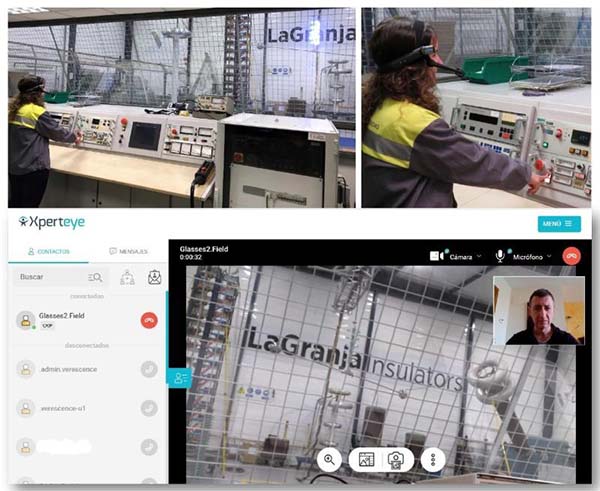

COVID-19 has revealed the compelling need for a remote inspection solution in order to sustain operations in any situation. To address this issue, the XpertEye Assisted Reality solution provides direct visual interactions between a remote expert and a factory technician so that they can perform acceptance tests in a very precise manner. The technician, equipped with smart glasses, and the remote observer can exchange visual indications live, via the video feed or via annotations added to photos taken on site. The solution can also take advantage of other connected devices such as endoscopes, microscopes, fixed or thermal imaging cameras to improve the inspection accuracy. AMA also offers a complementary solution: XpertEye Proceed. With Proceed, a manufacturer can carry out inspections according to procedures defined in advance with a customer. This allows them to check every step, take notes and record proof of a potential non-compliance by taking photos and recording sound and/or video.

As a complete solution, XpertEye can bring together multiple experts and technicians during the tests, promoting knowledge transfers. At the same time, it reduces travel, improves the accuracy of inspections and thus guarantees the compliance of any equipment.

Meeting La Granja Insulators’ needs with XpertEye

Many industrial manufacturers are considering new systems and opting for these innovative solutions. This is true for La Granja Insulators, XpertEye user. They explain in their LinkedIn post: “We need to be creative, thinking out of the box to tackle the challenges this new situation is bringing us. At La Granja Insulators, working out new solutions to face the difficulties is a part of our culture, so we implemented a new system of remote access with special smart glasses: this new Industry 4.0 #CollaborationTool enables remote attendance of our customers to witness Factory Acceptance Tests and Type Tests in our laboratory.”